Automatic intermittent piston pump MMX-2

Specifications Pump Discharge Volume 1.5〜2.5ml/stroke 2.5〜5.5ml/stroke Discharge Pressure 0.4MPa Motor (Other voltages available.) Voltage / Current AC100Vφ1/0.23A AC200Vφ3/0.11A (50Hz) AC100Vφ1/0.23A AC200Vφ3/0.10A (60Hz) Output 5W MInduction motor, E class Emergency Detection Oil level Oil level switch Contact Type AContact (NO) (ON at low level) Contact capacity 0.5A、AC DC200V/30Wsmaller Operation Rating Continuous Working Viscosity Range 32〜1300mm2/S Reservoir Capacity 1.8l、3l […]

Detail infor

Specifications

| Pump | Discharge Volume | 1.5〜2.5ml/stroke 2.5〜5.5ml/stroke |

|---|---|---|

| Discharge Pressure | 0.4MPa | |

| Motor (Other voltages available.) |

Voltage / Current | AC100Vφ1/0.23A AC200Vφ3/0.11A (50Hz) AC100Vφ1/0.23A AC200Vφ3/0.10A (60Hz) |

| Output | 5W MInduction motor, E class | |

| Emergency Detection | Oil level | |

| Oil level switch | Contact Type AContact (NO) (ON at low level) | |

| Contact capacity 0.5A、AC DC200V/30Wsmaller | ||

| Operation Rating | Continuous | |

| Working Viscosity Range |

32〜1300mm2/S |

|

| Reservoir Capacity |

1.8l、3l (plastic) 3l、4l、8l (sheet metal) |

|

| Weight | 3kg (1.8l plastic) | |

| Other | Rotary directions : Clockwise A 2µF condenser for the 100V motor is integrated into the terminal box. |

|

Replacement Motor Model

| Model | Voltage |

|---|---|

| N-02 | AC100Vφ1/5W |

| N-10 | AC200Vφ3/5W |

| N-08 | AC200Vφ1/5W |

Directions for use

| ● | Do not remove the oil strainer to keep the pump clear of foreign matter. |

| ● | Replace or clean the suction filter at least once a year. Click here to view the service list. |

| ● | Oil viscosity varies with oil temperature. Be sure to use oil within the working viscosity range. Refer to the viscosity table. |

| ● | Do not use any special additive-contained oil, water soluble oil and solvent. |

| ● | Periodically check the oil in the reservoir for impurities. Replace it, if necessary, with fresh oil immediately. Be sure to clean the reservoir before oil change. |

| ● | Make sure that proper voltage and pressure are proper. |

| ● | Do not overtighten the discharge joint. Refer to the tightening torque table. |

| ● | Do not press the discharge volume adjusting knob down by force. |

| ● | Adjust discharge volume only when the piston is fully relaxed ( The knob is at the lowest position.). |

| ● | Please check the direction of rotation of the Motor. Please do not upside down or Back the Pump. 三相結線のU、Wを変更して回転方向を変えてください。 |

| ● | For system planning information, Contact us. |

Discharge Volume Adjustment

Document

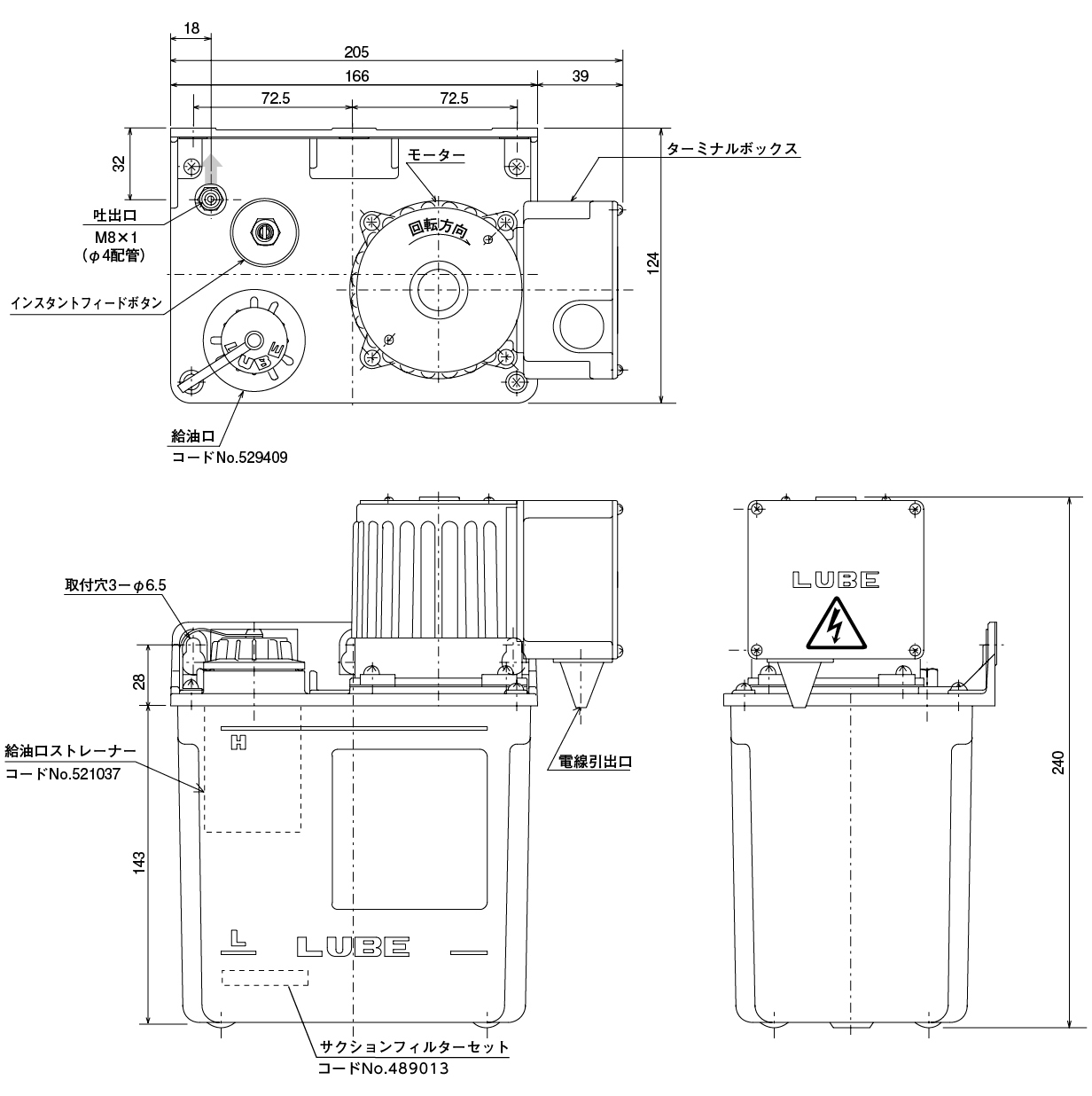

Pump Drawing

Wiring digram

Dimensional Drawing