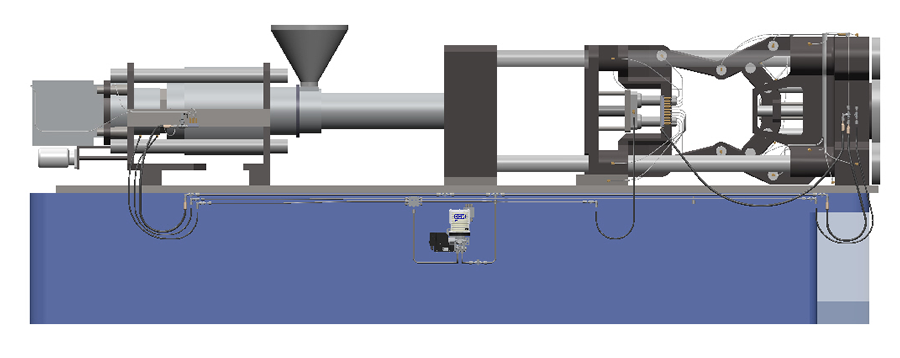

1.Development history of genuine grease.

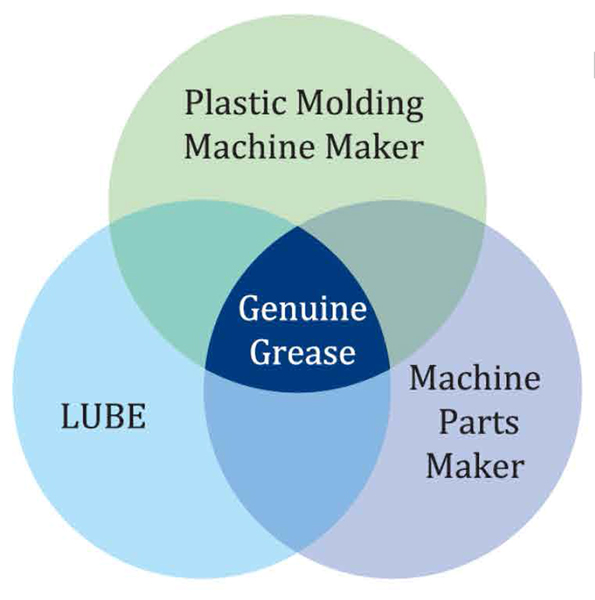

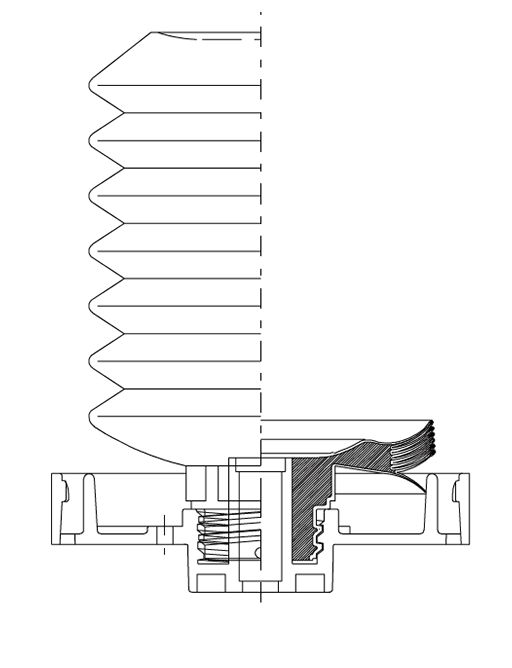

Since 17 years ago, the injection molding machine industry has adopted and produced an electric drive molding machine that excels in hydraulic pressure, high precision stable molding, and energy saving. Since the internal structure of the molding machine has changed drastically, and the structure has been changed mainly to “ball screws for high loads”, a grease agent for high loads corresponding to it has become indispensable. At Lube, “We have developed a high-load cartridge grease that can be sent with a centralized greasing device.

We perform reliable lubrication based on a system evaluation test using a combination of genuine grease and a grease system.

Plastic Molding Machine Maker

-

Ideal Lubrication Conditions.

-

Ideal Lubricants.

-

Maintenance.

-

Moderate volume of lubricants.

LUBE

-

Various Environments and the Operating Conditions.

-

Evaluation & Judge of the Optimum Lubrication Systems.

-

Performance Evaluation Tests about grease solidification, penetration & adhesion.

2.Comparison with non-genuine grease

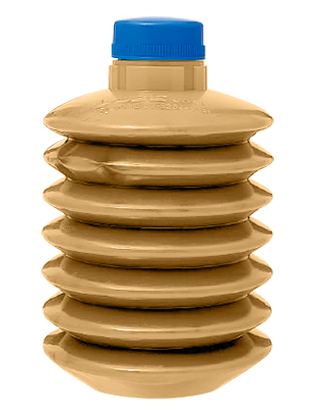

2-1. About Lube Original Grease (Comparison of container shape and residual rate)

| Genuine cartridge | Non-genuine cartridge | |

|

|

|

|

|

|

| Already used |  |

|

| Remaining amount of grease | 28 ml | 75 ml |

| Remaining rate | 4.0% | 10.5% |

2-2.About Lube Original Grease (Performance Evaluation)

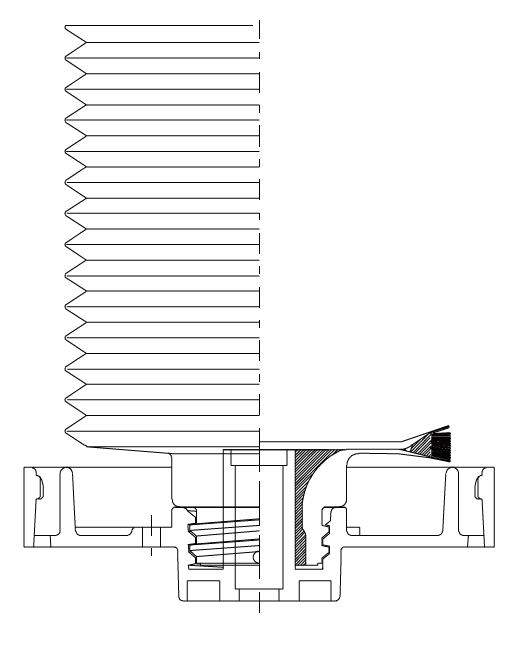

Load capacity

| Genuine cartridge | Non-genuine cartridge | |||

| High-speed four-ball Load capacity N |

LNL | ASTM D2596 | 1236 | 1236 |

| WL | 3923 | 3089 | ||

| LWI | 650 | 589 | ||

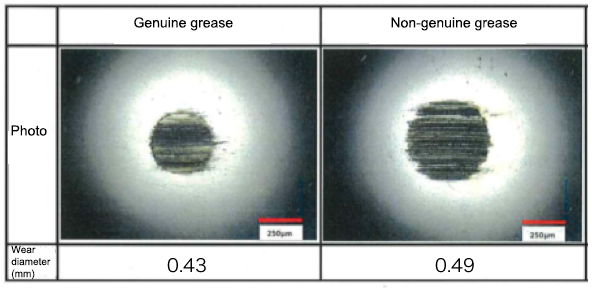

Abrasion resistance

Four-ball wear test results (75℃,40Kg,1200rpm,1h)