| Verification of grease lubrication system according to actual machine |

We perform reliable lubrication based on a system evaluation test using a combination of genuine grease and a grease system.

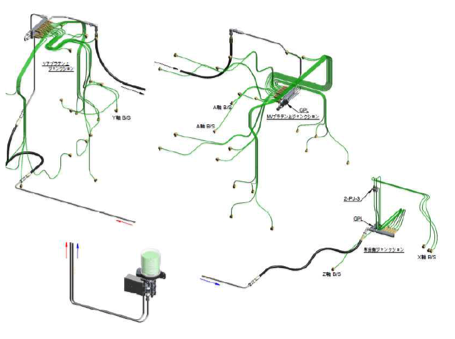

The electric molding machine has a lubrication system as shown above.

Necessary conditions for grease system design

【Necessary conditions for grease system design and verification】

- Grease agent

- Grease pump

- Piping layout of actual machine

- Pipe length (main pipe, greasing pipe)

- Plumbing

- Pipe inner diameter

- Valve discharge rate

- Operating environment temperature

※ Please consult us when designing a lubrication system.

We also check the actual lubrication layout and actual system to see if the system can reliably supply grease.

Pressure sensor installation example

It is also possible to install a pressure sensor at the end of each main pipe and near the pump discharge port and let us confirm the safety of the lubrication system.

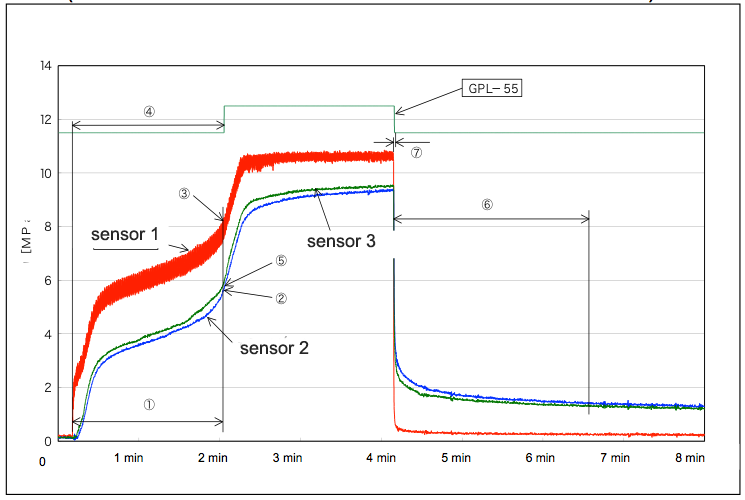

Example of grease system pressure evaluation test

(Evaluation test using genuine grease and system layout of actual machine)

Non-genuine grease is not used for system evaluation test. If the grease is different, the grease system will not operate safely.